Equipment Health check, Kiln Alignment studies, Kiln / Mill major repairs, Spares supply

A team of experienced professionals is available to check / assess the physical health of any old or operating plant machinery /equipment to ascertain its long term performance.

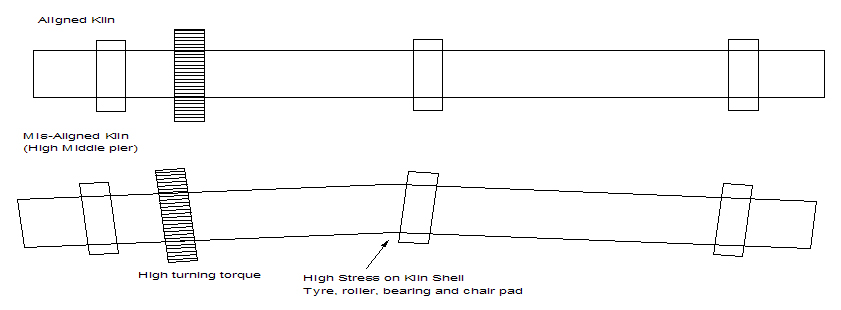

Kiln, the heart of a cement plant, is a robust rotating structure and can operate silently without much noticeable problem over a period of time. Any stoppage in kiln corresponds to direct loss of production. Being a rotating machine, deviations do creep in with time, affecting the kiln alignment resulting in unstable operations.

Unstable operations induce stress and fatigue on kiln shell, tyre and mechanical rolling elements, resulting in wearing of roller / tyre surface, roller bearings etc. Misaligned kiln consumes additional power to overcome the turning torque.

Hot Kiln Alignment: We undertake the hot kiln alignment studies for checking the mechanical condition of kiln like:

- Profiling of kiln shell to identify deformations using high quality precision instruments

- Condition of kiln inlet and outlet seals

- Contact of support rollers with tyres

- Migration of tyres, condition of chair pads

- Root gap and backlash measurement in Girth gear and pinion

For kiln alignment studies we have teamed up with M/s Allan Smith Engineering, (who are certified partners of Euro Kiln) under the leadership of Expert Mr Shailesh Kumar, a professional with more than 30 years of experience in Kiln alignment.